The term ‘Supplier Quality’ refers to a certain supplier’s ability to deliver the required goods or services with a satisfactory standard that meets the needs of the customer. While it is assumed that organizations strive to acquire the best deal in a bulk purchase or a low purchase price, the reality is far beyond these traditional needs of the market. In simple words, Supplier Quality Analysis implies the process by which suppliers are tested on their ability to provide high-quality products and services while meeting the needs of the customers.

The test provides an in-depth understanding of the numerous parts of the supply procedure. The continuous improvement in the supplier quality management systems is motivating business improvement across all organizations in the market.

Supplier Quality Analysis using Power BI

Benefits of Supplier Quality Analysis in an organization:

The concept of supplier performance and quality management within the supply chain goes way beyond the intention of securing a low purchase price or a better deal on bulk materials. It includes a wide range of other fields that form a part of the supplier quality performance.

These consist of the cost of transportation and transactions along with the cost of communication and problem resolution methods with an option of switching suppliers. In addition to this, the internal policies of the suppliers and the extent to which the delivery system of the supplier could be trusted, also have to be considered.

The process of supplier quality analysis provides the customers with certain advantages that pave the way for customer advocacy and marketing. One of the most important advantages of the analysis of supplier performance is that the customer company can avoid costly yet devastating supply disruptions.

The other benefits can be categorized as:-

- The customer organizations gain the ability to reduce the risk of the occurrence of adverse scenarios like defective material, environmental issues, and safety problems related to the supplier’s product, material, or transportation.

- The companies with successful supplier quality management systems gain the ability to recognize the issues with the methods of suppliers and can begin implementing corrective actions.

- Companies with effective supplier performance management programs do not merely include risk mitigation. It also leads to improved communication and collaboration between suppliers and customer organizations.

- Improved efficiency and coordination patterns between the suppliers and companies can be established.

- Consistent supplier quality analysis leads to motivating the suppliers to undertake continuous quality improvement initiatives.

- Increased accuracy and reduction in expenses are the additional benefits which is a result of effective supplier quality management systems.

- Finally, when supplier processes undergo constant analysis, the resulting methods become capable of meeting all the major and minimum requirements of the customer organization.

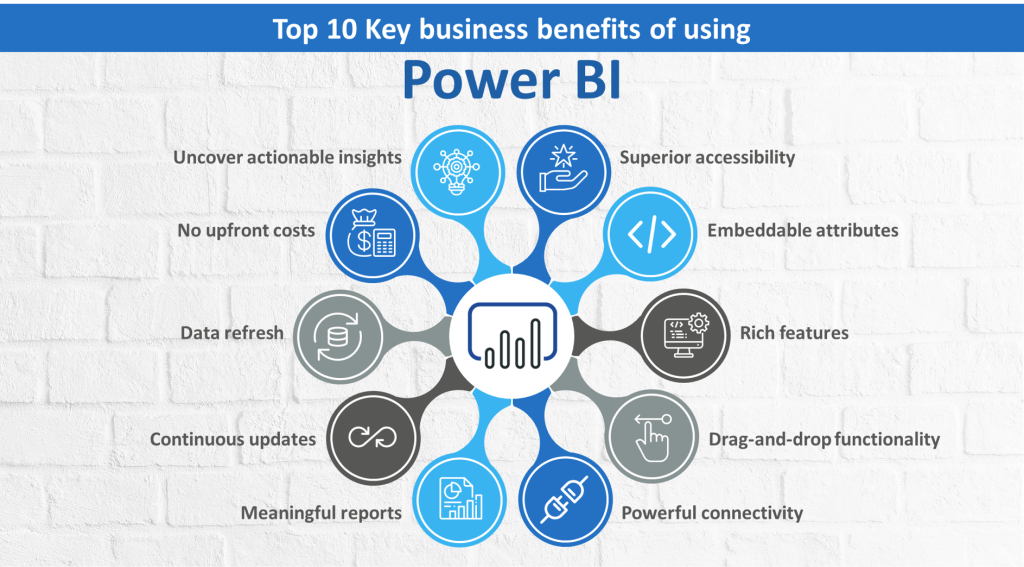

Role of Power BI in Supplier Quality Analysis:

Source – Link

The analytical skills coupled with the advanced analytical algorithms help the user companies to derive actionable insights from the supplier data. The resulting insights can also be streamed in real-time analytics and displayed through custom or standard visualizations that promote a better understanding of these insights.

A better understanding of the insights implies a direct improvement in decision making and the subsequent selection of capable suppliers for fulfilling the needs of the customer company.

Benefits derived by using Power BI as a Supplier Quality tool:

When an organization employs Power BI as its supplier quality analysis tool, it gains certain advantages along with the analysis procedure. One of the most crucial advantages includes reduced labor costs. As Power BI is a Microsoft tool, it has features that help the users to perform supplier quality analysis for supplier data.

The analysis of supplier data with the use of Power BI features allows the user organization to increase the individual analysis capacity of the data. As the Microsoft tool is capable of analyzing large quantities of data in a shorter period, better analysis of larger volumes of data can be completed within minutes.

The in-depth analysis features of Power BI help the customer company to understand and recognize the loopholes in the working patterns of the suppliers. This in turn helps these organizations in reducing risks related to default in delivery, poor quality materials, and others.

Real-time visibility and analytical skills:

Microsoft Power BI is designed with advanced analytical skills which help the user companies in gaining actionable insights. These insights in turn aid in transforming the organizational data into creating solutions for business problems.

The analytics features allow the user to view and monitor important performance indicators in real-time. This is specifically helpful in recognizing the metrics which drive better opportunities and success. In addition to this, the user organizations also have the scope of viewing the insightful data in the form of interactive visuals which help in improving their decision-making patterns.

The advanced analytical AI algorithms incorporated within Power BI make it capable of providing the users with newer ways to derive intuitive insights from the existing business data. As a result of these insights, the core business processes within an organization improve drastically.

In the context of providing better visibility of the business insights, Power BI can give this data visualization in real-time. This implies that the tool provides the user with a range of options related to visuals kept in the community gallery along with customizations that can be performed on the built-in visualizations.

Process of executing statistical analysis for supplier data using Power BI:

In a growing organization, new datasets are a part of its development. But to derive meaningful insights from these datasets, the company needs to employ tools or services that can perform statistical analysis of the data. In this context, Power BI has become increasingly popular. Statistical analysis of data helps the user in deriving insights from a certain dataset that had been previously missed out.

The method of running quick insights helps in generating interesting visualizations based on the data. Power BI also can run quick insights on entire datasets, a specific dashboard tile, or even insights themselves. The process of deriving insights from the data derived from Supplier Quality Analysis follows the below mentioned general method:-

- The Datasets + dataflows tab has More options(…) next to the dataset. Click on this and select GET Quick Insights.

- Power BI then uses various analytical algorithms to search for the trends in the dataset.

- Within a few seconds, the user organization is provided with insights from the organizational data. Then click on the View insights for displaying the visualizations.

- The resulting visualizations are displayed in the canvas of Quick insights which provides up to 32 different insight cards. Each of these cards displays a chart or graph along with a short description.

Such insights derived from the supplier quality analysis data give the customer company an in-depth understanding of the compliance gaps within the supplier’s processes. In addition to this, the customer company can also recognize the difference between quality products from cheaper goods and services.

Parameters for analyzing supplier quality performance using Power BI:

The process of Supplier Quality Analysis consists of a range of parameters on which a certain supplier is analyzed. These metrics have an influential role to play in the process of selecting a supplier. The parameters include the amount of downtime caused to the customer company due to defective materials, bad suppliers, and comparing plants.

The consideration of the downtime being caused due to defective materials is one of the crucial aspects to be considered by customer companies. In simple words, when a supplier does not have a proper quality control program in place, the cost of defective materials can find its way into the pricing structure. As a result, the manufacturing price of the customer also shoots leading to disruption in the manufacturing and order fulfillment process.

Suppliers that have no compliance aspects related to their working methods or Suppliers that work in patterns that have compliance gaps in the future prove to be the worst. One of the biggest reasons for this is the fact that these suppliers do not have any risk management plans or quality control plans ready for their customers. Thus, efficient supplier quality analysis helps the customer companies in avoiding the disadvantages that come with selecting bad suppliers.

EPC Group: A Power BI Consulting perspective

The EPC Group is one of the leading Power BI consulting partners in the business market. The organization has a holistic view of the method of deriving a strategy for curating data and implementing analytical skills for meeting the needs of the clients. With the belief that data and improved decision-making are correlated, the EPC Group employs customized training programs for their client organizations.

In addition to providing customized training programs and extensive consulting sessions, the EPC Group provides a clock customer support system. Being a gold-certified partner of Microsoft, the organization is highly adept in helping organizations in deploying Microsoft tools and services. Along with having over two decades of experience in Microsoft consulting services, the EPC Group has over 75 Power BI experts in their team who are capable of helping their clients derive the best out of Power BI.