Predictive asset management using Power BI is a process for finding potential equipment failures, analyzing the potential causes, and making plans to prevent loss. It involves collecting data about equipment performance and using that data to predict when equipment will fail. You can use the information to schedule maintenance activities or other preventive measures.

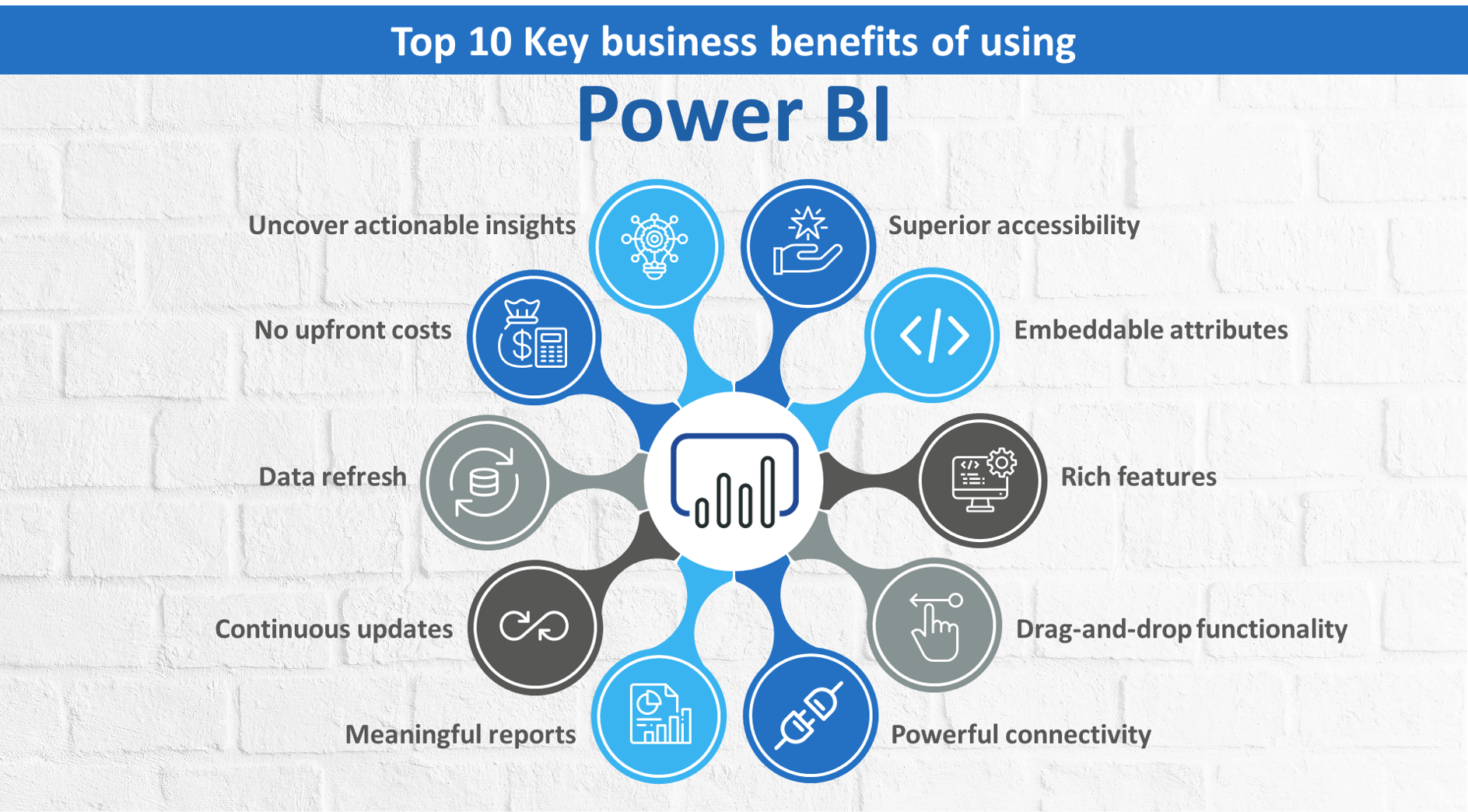

Companies are finding new ways to use data to get ahead of their competitors in a world where people are more connected than ever. One such method is predictive asset management. The Power BI suite of tools is an excellent way to visualize this data, as it allows users to easily create interactive reports that multiple employees across an organization can use.

Increasing the Performance of Predictive Asset Management

Power BI offers an end-to-end platform that allows you to use your industrial assets more efficiently. It also enables you to manage and analyze data better, including data from sensors and Enterprise Information Management systems, as well as external sources. Ways to increase the performance of Predictive asset management:

Surge Your Asset Performance

Asset performance optimization is an intelligent way to forecast repairs and perfect maintenance to reduce downtime and save hundreds of millions of dollars for a large industrial organization.

Power BI merges sensor data with product specifications and documentation, weather pattern information, compliance requirements, field service technician availability, and data from financial, supply chain, and procurement applications to achieve these goals. It uses Artificial Intelligence to analyze patterns, detect anomalies before they occur, and trigger business actions, such as alerts to stakeholders.

Reduce Maintenance Costs by up to 25%

As your business grows, so do your maintenance costs. What if there was a way to reduce those costs by up to 25 percent?

That is what asset performance optimization can do for you. Asset performance optimization uses AI (Artificial Intelligence) and analytics to analyze your assets and predict when they need maintenance before breaking them down. This way, you can avoid unnecessary labor costs resulting from unplanned repairs and extend the life of your assets by 20–40 percent.

This process helps you:

- Increase margins by increasing output.

- Satisfy customers by reducing quality defects and delays.

- Reduce capital investment due to longer asset lifetime value.

Improve Maintenance Safety

As you know, a malfunctioning machine can cause severe injury to your employees.

Unfortunately, organizations are not usually aware that a machine is about to misfunction until it is too late. Fortunately, preventative maintenance can improve maintenance safety by up to 14 percent.

Using AI and data analysis, Predictive asset management from Power BI can predict problems and reduce the number of workplace incidents for employees.

Optimizing asset performance through data analytics

The way to perfect asset performance is through data analytics. Business leaders responsible for asset performance depend on data to make decisions about maintenance schedules, parts procurement, and retirement of industrial assets. As per one of the market studies, empowering supply chain executives with Data analytics so they can decide based on data-driven insights will lead to a 15 percent revenue growth and operating margin.

The Impact of Predictive Asset Management on Revenues and Growth

Predictive asset management significantly affects revenues, growth, and profitability. Here are some of the advantages of using predictive asset management.

Improve Business and Operational Efficiency

To improve business and operational efficiency, organizations can use the predictive capabilities of analytics to predict the completion of ongoing tasks. This process means managers can distribute resources to new projects based on near-accurate predictions of when you will complete ongoing tasks.

Similarly, companies can ask HR departments to hire more staff if they expect workloads soon. In sales, exact forecasts are critical for budget allocation, demand and supply management, performance incentivization, and business roadmap preparation.

Understand Market Trends

These tools use statistical techniques to model data based on click-through, bounce, churn rates, and more to offer insight into what customers think of and expect from your product or service. This information can help companies design winning marketing campaigns and reach the right customers.

You can run models with historical data, A/B testing results, heatmaps, and other conversion testing tools to forecast how your customers will respond to changes to a given variable.

Risk Analytics Predictive Modeling

The field of risk analytics is growing as increased businesses look to data mining techniques and machine learning algorithms to help them predict the future.

Risk analytics can help enterprises decide the probability of growth or decline in business based on current and historical information. Data mining techniques and machine learning algorithms deliver high-quality predictions as they become more correct.

Helps Secure Online Data

Businesses collect online data for a variety of purposes. This process can include consumer goods purchases, consulting physicians, banking, and investing and trading in stocks.

Each of these tasks involves sensitive data, which means that users are vulnerable to identity theft and fraud if they input personally identifiable information (PII) and sensitive financial details online. Online service providers use predictive modeling to analyze historical data and find gaps and discrepancies in existing workflows.

How Predictive Analytics Is Impacting Predictive asset management and Business Processes

A predictive analytics model is a mathematical algorithm that uses historical data to predict the future. As with any other mathematical model, it requires some assumptions, which are based on the data and can vary depending on the type of model building.

Once you have developed your Predictive asset management, it is essential to understand how you will use it before deploying it for real-world use. The business process will help ensure you get the maximum benefit from using your predictive analytics model in your business process.

Predictive analytics is a broad term used to describe data, technology, and algorithms to predict future events. Predictive analytics can help organizations in several ways, including improving processes, finding risk or fraud, and improving customer service.

The advantages of Predictive asset management are now more accessible than ever because of the increasing amount of data, software availability, and powerful hardware. However, analytics alone will not solve the problem. Gaining business advantage from the ever-increasing amount of data and low cost of computing power. Instead, the answer consists of several steps:

- They understand the business problem.

- We are working out the data needed.

- Finding what data is available.

- We are designing and building a credible and practical solution to the business problem that uses available data and proper analytics.

- We are implementing the solution.

How Predictive asset management Helps Companies Reduce Cost and Improve Safety

The industrial world is getting more intelligent and more connected. Sensors and connected IoT devices are generating piles of data in real-time. Predictive asset management gives users the tools to turn raw data into actionable insights, which you can use to keep equipment reliability, performance, and safety.

Quickly transforming raw data into actionable insights is essential for companies that rely on critical assets such as power plants, refineries, or oil rigs. Improving reliability, performance and safety are among the top priorities of industrial plants and other asset-intensive organizations today. Businesses are focusing on controlling costs and maximizing value from investments already made.

Power BI can help companies reduce costs and improve safety by allowing them to address issues before they become problems that significantly affect operations. With continuous maintenance and reliability improvements, you can achieve added benefits.

You can reduce unscheduled downtime because personnel receives early warning notifications of developing issues. Instead of shutting down equipment at once, you can assess the situation for more convenient outcomes. You can also reduce maintenance costs due to better planning; parts can be ordered and shipped without rush, and equipment can continue running.

Conclusion

Predictive analytics is a powerful tool! Organizations can use this technology to find and sometimes prevent equipment failures that would otherwise cause monetary loss, significant downtime, or other disruptive effects. The Microsoft Power BI tool offering predictive analytic capabilities is available through Microsoft Azure and is fully managed and scales to the performance so that organizations can easily analyze large volumes of data. EPC Group can help you harness the power of predictive analytics in Power BI to get rich visualization, business intelligence, and executive dashboards.